The Water Crisis in the Textile Industry

The textile industry is one of the largest consumers of water, with massive amounts used in every stage of fabric production. From pre-treatment processes like washing, bleaching, and scouring to the dyeing and finishing stages, water plays a crucial role. However, this dependence has led to severe environmental pollution. It takes around 1,500 gallons of water to produce a single pair of blue jeans, and dyeing just one kilogram of textile material requires 100-150 litres of water. According to the World Bank, textile dyeing contributes to 17-20 per cent of global industrial water pollution.

As the world faces an increasing water crisis, textile companies are turning to new, sustainable alternatives—one of the most revolutionary being waterless dyeing techniques. These innovative methods eliminate or significantly reduce the use of water while ensuring vibrant, long-lasting colours in fabrics.

What is Waterless Dyeing?

Waterless dyeing is a revolutionary technique that eliminates water and harmful chemicals from the dyeing process. Instead of submerging fabrics in liquid dye baths, this method directly integrates colour into the textile fibres before they are spun into yarn. Several waterless dyeing technologies have emerged, each offering significant environmental benefits.

Types of Waterless Dyeing Technologies

1. Supercritical Carbon Dioxide (CO₂) Dyeing (Dry-Dyeing)

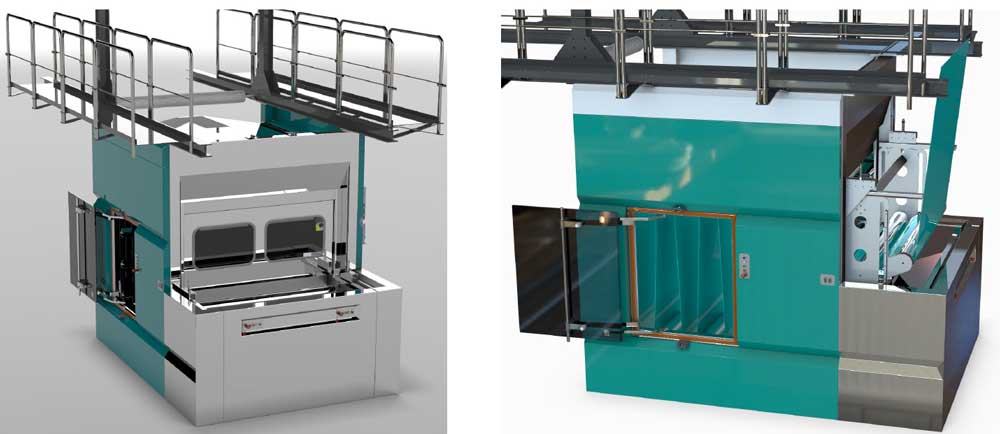

Image Source: dyecoo.com

One of the most promising waterless dyeing innovations is supercritical carbon dioxide dyeing. This technique, pioneered by Dutch company DyeCoo, uses carbon dioxide in a supercritical state, meaning it has both gas- and liquid-like properties.

When heated above 31°C and pressurised beyond 74 bar, CO₂ becomes a highly effective solvent for dissolving dyes. CO₂ is introduced into a dyeing vessel containing fabric. Heat and pressure turn it into a supercritical fluid that carries dye molecules deep into the fibres. Once the dyeing process is complete, CO₂ is depressurised and recaptured for reuse, making it a closed-loop system with zero wastewater.

2. Air Dye Technology

Developed by Colorep Inc., Air Dye technology uses heat and air instead of water to transfer colour onto fabric. Dyes are converted into gaseous form and embedded into textiles without requiring water. This results in high colour accuracy and vibrant, long-lasting hues. The technology ensures even dye penetration, reaching filaments inside the yarn rather than just coating the fabric’s surface. This method has already been adopted by sustainable fashion brands looking to reduce water and energy consumption.

2. GreenDye by Karl Mayer

Image Source: innovationintextiles.com

GreenDye is a patented indigo dyeing technology that eliminates water usage while using 50 per cent fewer chemicals than traditional dyeing methods. Instead of liquid dye baths, nitrogen-rich environments help distribute colour evenly across denim fabrics. Compared to conventional methods, GreenDye technology increases dye absorption by three times, ensuring deeper colour saturation.

Advantages of Waterless Dyeing

• Drastic Reduction in Water Consumption – With waterless techniques, textile manufacturers can drastically reduce their reliance on freshwater, preserving this scarce natural resource.

• Minimal Wastewater & Pollution – Traditional dyeing releases toxic wastewater into rivers and oceans. Waterless dyeing methods prevent this, ensuring zero water pollution and protecting aquatic ecosystems.

• Energy Efficiency & Cost Savings – Waterless dyeing techniques reduce processing time and energy consumption, making them more cost-effective in the long run.

• Enhanced Colour Precision & Fabric Quality – These innovative techniques ensure better colour accuracy, consistency, and durability compared to conventional methods.

A Promising Future for Waterless Dyeing

The demand for freshwater is growing, and sustainability has become a key focus in fashion and textile manufacturing. Leading brands are increasingly shifting towards waterless dyeing methods to reduce environmental impact and meet consumer demand for eco-friendly fashion.

Image used for representational purposes only.